|

Description

BT103S speed-variable peristaltic pump adopts high quality closed-loop stepper motor drive, speed range 0.1~100rpm, speed accuracy<±0.2%,one channel flow range0.0001~480ml/min. Through Lead Fluid APP software, the pump can be controlled remotely and running status can be monitored in real time.RS485 communication, MODBUS protocol is available,the pump through a variety of signal modeis easier to be connected with other equipments, such as computer, human machine interface and PLC .

Functions and Features

|

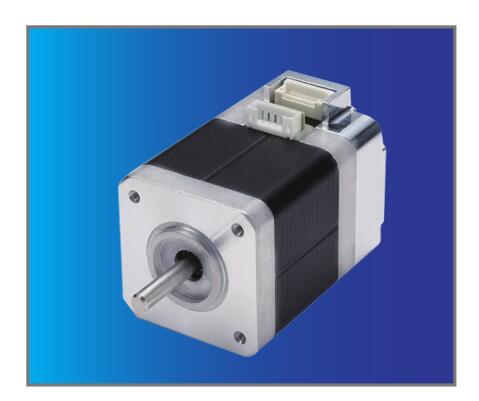

High Precision Motor

High precision stepper motor

Speed accuracy<±0.2%

Closed-loop control

|

|

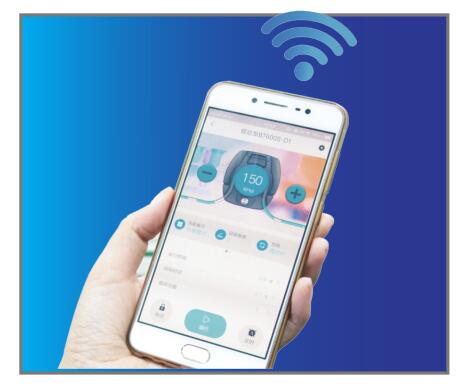

Intelligent Cloud Control

Wifi function

Support mobile phone App remotely control

|

|

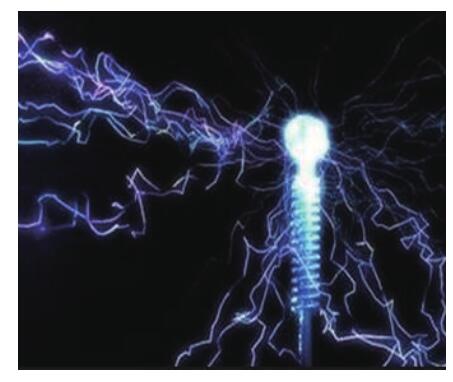

Anti-Interference

Super anti-interference feature

CE certifaction guarantee

|

|

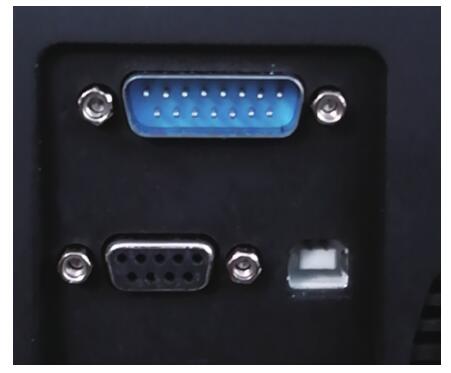

External Control Function

Powerful external control function

Support 5~24V wide voltage input

RS485 interface

MODBUS communication protocol

|

|

Exquisite Appearance

ABS injection molding shell

Streamline design

Simple and beautiful

|

- LF-LED-OS software system, high definition lattice LCD display,switching between Chinese-English,parameter setting simplely,intuitive state display.

- Industrial mask keypad operation, simple and convenient, high durability.

- High quality closed-loop stepper motor drive, speed precision, running stability,high-precision flow transmission.

- Start/Stop, adjust speed, reversible direction, full speed and,state memory (power-down memory).

- Can set the parameters of running time, interval time and cycle times to meet the requirements of timing, quantitative, liquid dispensing and

flow testing.

- Slow speed stop and suction function, which can effectively prevent the dropping of liquid when the machine stops.

- Keypad locked function to prevent misoperation.

- The remote start-stop, adjust speed and timing operation can be realized through LeadFluid APP software. It also has monitoring functions

such as stop alarm, change of pump tube and so on.

- Streamline injection molding shell design, simple, beautiful and easy to clean.

- The circuit board with conformal coating makes it dust-proof and moisture-proof.

- Super anti-interference feature, wide input voltage range, acceptable for complex power environment.

- External analog adjust speed , external control start-stop ,reversible direction, external control signal physical isolation.

- RS485 communication interface, Modbus protocol is available, support settinig communication parameters, easy to connect with various control devices.

- Can match various high performance pump head,realize different pump head and drive combination.

- Support blocking turn alarm , leakage alarm (optional).

- Thermal printer can be connected, real-time printing operation parameters (optional).

Specifications

| Flow range |

0.0001~480ml/min |

| Speed range |

0.1~100rpm |

|

Speed resolution

|

0.1 rpm |

|

Speed accuracy

|

<±0.2%

|

|

Display mode

|

Window77x32mm, Monochromatic 132*32 lattice liquid crystal

|

|

Language

|

Switching between Chinese and English

|

|

Operation mode

|

Industrial mask keypad

|

| Operation mode |

Long press direction keypay to lock, long press start and stop key to unlock. |

| Timing function |

Timing running time 0.1-999 S/Min/H/D,interval time

0.1 -999 S/Min/H/D |

| Cycle times |

0~999(0 Infinite cycle ) |

| Back Suction angle |

0~720° |

| External control signal input |

Start /Stop: passive contact, external control input level 5-24V. Reversible direction: passive contact, external control input level 5-24V. Adjust speed: analog quantity 0-5V,0-10V,4-20mA can set. |

| External control signal output |

Start /Stop : level signal (following input voltage). Reversible direction : level signal (following input voltage). Speed state: analog quantity 0-5V. |

| Communication interface |

RS485, MODBUS protocol is available,DB15 external control interface. |

| Power supply |

AC100~240V ,50Hz/60Hz |

| Power consumption |

<30W |

| Working environment |

Temperature 0~40℃, relative humidity<80% |

| IP Grade |

IP31 |

|

Dimension

|

232x140x145mm

|

|

Drive weight

|

2.9 kg

|

Applicable Pump Head and Tube, Flow Parameters

|

Pump Head

|

Channel Number

|

Tube

|

Per Channel Flow Rate(mL/min)

|

|

DG6(6 rollers)

|

1,2,4

|

Wall 0.8~1mm,ID≤3.17mm

|

0.0002~49

|

|

DG10(10 rollers)

|

1,2,4

|

Wall 0.8~1mm,ID≤3.17mm

|

0.0001~41

|

|

DT10-18

|

1

|

13#14#, Wall 0.8~1mm,ID≤3.17mm

|

0.0002~82

|

|

DT10-28

|

2

|

13#14#, Wall 0.8~1mm,ID≤3.17mm

|

0.0002~82

|

|

YZ15

|

1

|

13#14#19#16#25#17#

|

0.006~280

|

|

YZ25

|

1

|

15#24#

|

0.16~280

|

|

YT15

|

1

|

13#14#19#16#25#17#18#

|

0.006~380

|

|

YT25

|

1

|

15#24#35#36#

|

0.16~480

|

Dimension

|

|

|

|

| Payment Terms︰ | T/T,Paypal,Western Union |

|

|

Product Image

|